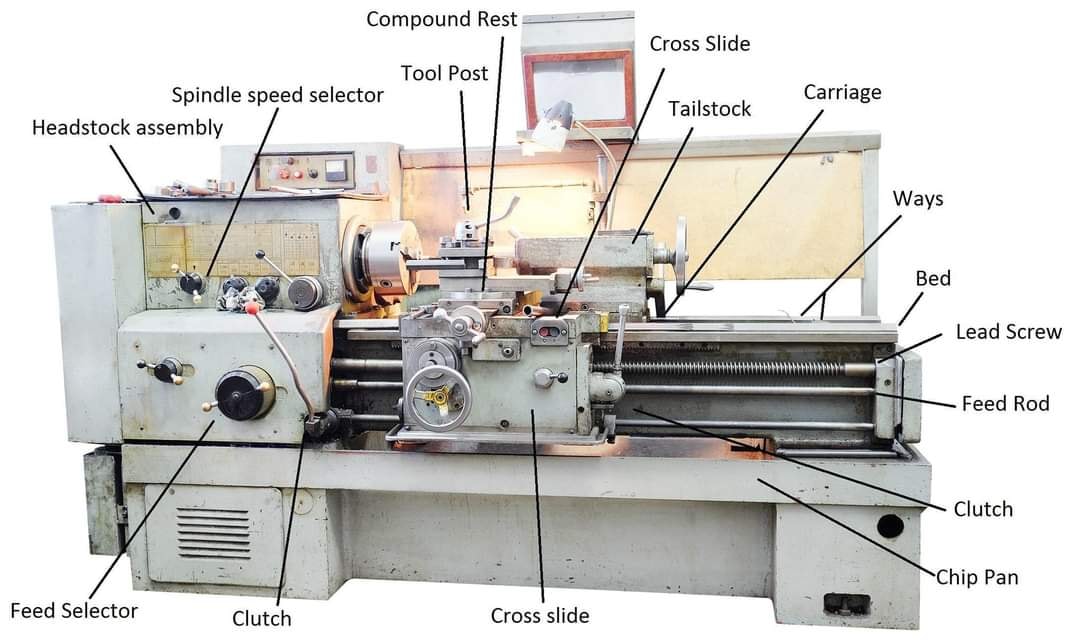

Lathe Machine or Turning Machine have totally four parts

1.Lathe Bed

2.Head Stock

3.Tail Stock

3. Carriage

1. Lathe Bed

Simply put, a lathe bed is the main body of a machine. The rest is on the Lathe Bed. On the Lathe Bed are the rest of the Head Stock / Tail Stock / Carriage. The top surface of the lathe bed has a guide way to move the carriage, tail stock and sliding motion.

2. Head Stock

The head stock refers to the metal casting hive attached to the spindle at the top left of the machine. The head stock includes the main spindle. The head stock section includes connections for motor rotation and spindle rotation. Lever / Gears / Bearings are included to adjust the spin speed.

3.Tail Stock

Tail stock is used to prevent the shaft from shaking when long spindles are mounted on the spindle / chuck / jaw. As a workpiece, the ball center / dead center is held in place by one end of the machine to prevent eccentricity during machining. You can also install the tool on the tail stock for drilling / boring operations. The inner sleeve of the tail stock is made of Morse Taper, so you can install the appropriate tools. The tail stock can be moved on the lathe bed and controlled by a locking lever.

4.Carriage

The main function of the carriage is to capture the spinning tools and transport them to produce the cutting and adjusting motion of the cutting tool. The carriage consists of a slide and a cross slide, which is moved by their lead screw to create a Feed Motion and Adjusting Motion.

Turning Process

At the cutting edge of the bench, the cylinder-shaped workpiece is held by a chuck and the spindle rotates. The cutting tool mounted on the spindle is cut by the cutting edge of the cutting tool. The cutting tool mounted on the cutting tool moves on the guide way. By moving the cutting tool, the unwanted parts of the workpiece are cut into chips. In spinning process, the spin / rotation of the workpiece is called the Cutting Motion (or) Main Motion.

The speed at which the cutting tool comes in contact with the cutting edge of the cutting tool is called the cutting speed. The cutting tool moves the slide to the desired depth inside the workpiece and cuts it into chips. The cutting tool and the workpiece are used to cut into the workpiece. Depth of cut depends on the material. Cutting Tool.

The movement of the cutting tool is called Adjusting Motion. Once the Depth of Cut is reached, the cutting chip is removed by moving the cutting blade toward the Head Stock / Chuck. This movement between the workpiece and the cutting tool and moving toward the chuck is called feed motion. Therefore, the cutting speed is the rate at which the chip removal occurs when a combination of Adjusting Motion and Feed Motion occurs.

Type of Lathe Operations

1.Chucking

2.Facing (Adjusting the edge of the workpiece (side with tail stock))

3. Centering (Finding / revealing the center point of the workpiece)

4. Straight Turning (eating evenly around the workpiece top / inside surface)

5. Taper Turning

6.Drilling

7. Boring (Drilling a hole drilled with a Boring Tool)

8. Reaming (Finishing / enlarging the hole with Reamer)

9..Threading (or) Thread Cutting (inside / outside)

10. Knurling (Knurling Tool – Knitting – Handle / Handwheel)

11.Cutting (or) Parting